Fabric tensile strength plays a crucial role in the quality and performance of fabric. Materials with higher tensile strength are more durable, as they can withstand greater stress and strain without failing. They’re less likely to tear or develop holes, therefore increasing their life span.

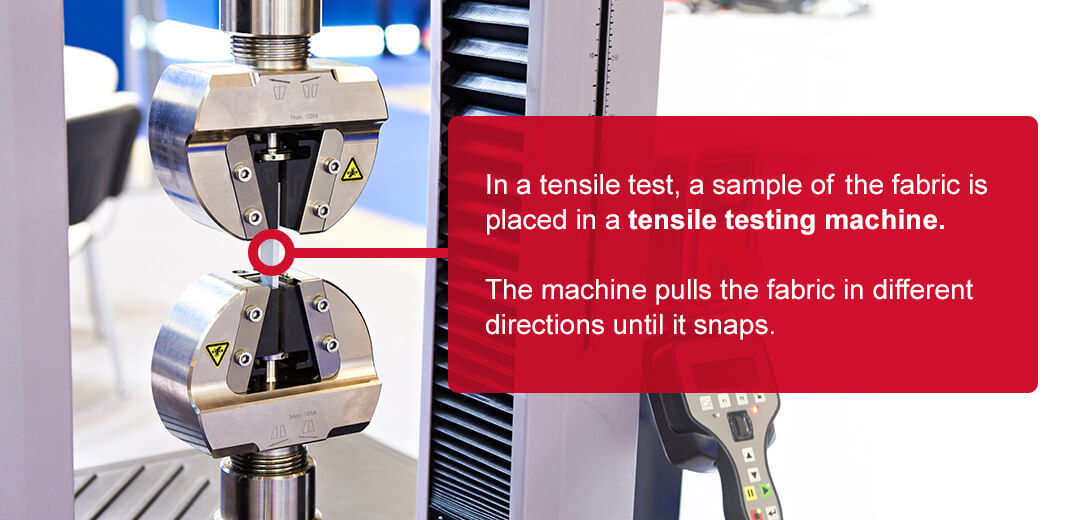

Tensile strength is particularly important where fabric is used for structural purposes, such as for architectural membranes or in asset protection, like covered parking structures. Fabrics with sufficient tensile strength can provide stability and support to different kinds of structures, ensuring they can withstand external forces. Knowing how to accurately measure fabric tensile strength helps you choose suitable options for your applications.

What Causes Problems in Fabric Tensile Strength?

High tensile strength indicates that fabric will be less likely to suffer wear and tear while in use. Fabric with higher tensile strength and performance are more suitable for products and applications in industries that require durability, versatility, and low maintenance.

Manufacturers and researchers can make informed decisions about a material’s suitability for different applications when they know of the factors affecting the tensile strength of fabrics. These elements can lead to issues with fabric tensile strength:

- Fine material composition: Different types of fabric have varying levels of strength, density, and elasticity. Coarse materials generally are stronger than fine materials.

- Weak weave patterns: The weave pattern used can influence fabric tensile strength. Plain weave patterns are stronger than twill since the density of warp and weft strengths are higher.

- Environmental factors: Long and regular exposure to heat can lower the tensile strength of fabrics. Moisture can also negatively affect tensile strength depending on the type of fabric.

- Fabric treatments: Some treatments can reduce a fabric’s tensile strength, while polyvinyl chloride (PVC) and polytetrafluoroethylene (PTFE) add to its strength and life span. Consider the impact of the fabric’s treatment and how specific treatments may create a stronger fabric.