Most modern buildings are compression structures, where blocks or bricks are piled on top of one another to form walls or create frames to hang rigid materials from. Another way to build structures is using flexible materials and the force of tension. Tensile architecture is a twenty-first century method based on tents, one of the oldest and simplest methods of providing shelter.

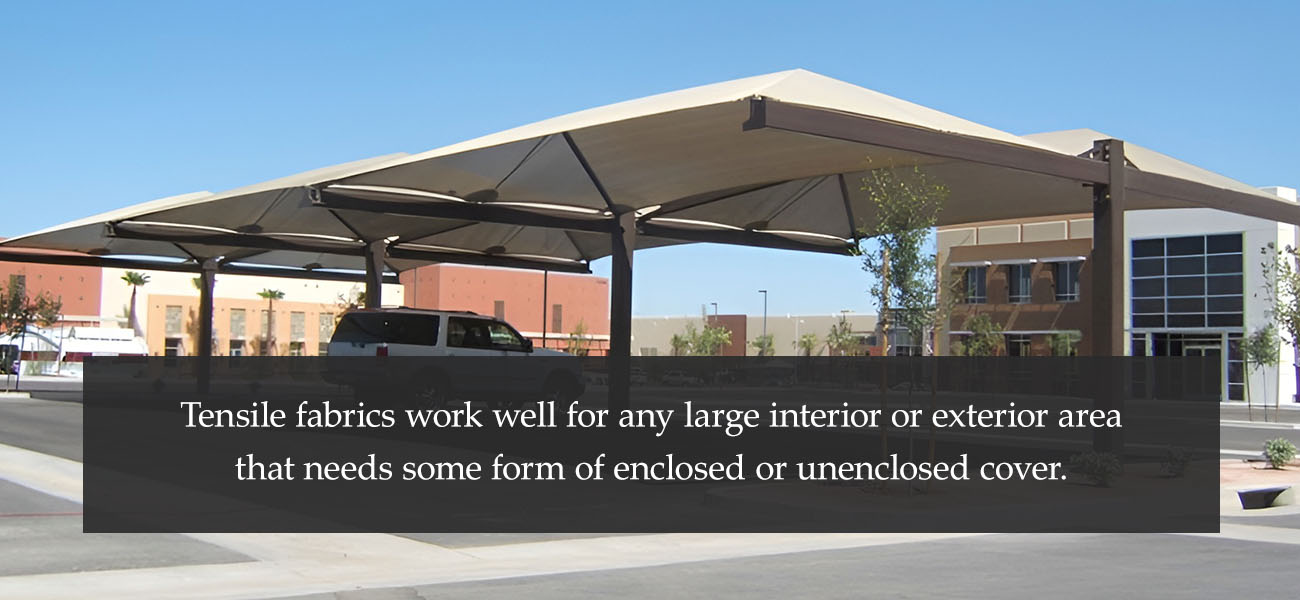

This post explores a broad overview of what tensile fabric is, what it’s made of, and its uses and benefits in tensile fabric structures. Tensile fabric offers various possibilities for free-form structural designs using flexible materials. One of the main applications of tensile fabric structures is to provide cover from harsh environments.

What Is Tensile Fabric Made Of?

Tensile fabric material can fall under two categories — coated and mesh. Coated tensile fabrics are typically used for external purposes. These fabrics are made of woven cloth fabrics and stabilized with a protective coating. Mesh fabrics are coated cloth with small spaces between the thread bundles, and are more commonly used for interior applications.

Fabric materials are considered to be more sustainable than traditional building material options. Although tensile fabric comes in different varieties, the two most common coated fabrics used in tensile structures are polyvinyl chloride (PVC) and polytetrafluoroethylene (PTFE).

PVC COATED POLYESTER

Tensile fabrics coated with PVC can be used in both permanent and temporary structures. The PVC coating includes ultraviolet (UV) stabilizers, fire retardant additives, and fungicides. It also has good resistance and is low-maintenance.

PVC-coated fabrics are commonly used in tensile structures due to their greater durability, translucency, and affordability. These tensile fabrics can have a structural life span of 20 years due to the material’s strength and high flexibility. Adding extra UV protection and fire retardants in the coating can help increase the longevity of the fabric.

PTFE COATED GLASS CLOTH

PTFE-coated glass cloth is a high-quality material used in tensile fabric membranes. For those who prefer ultra low-maintenance structures, this high-quality fabric provides the additional benefit of a 30-year life span or longer. Cleaning is typically recommended only every 2-5 years, and rain may provide some degree of cleaning on the outer layer. This material also resists buildup due to environment pollution and will not discolor or become brittle over time.

Although it is more costly than PVC, PTFE-coated tensile fabrics are sturdy and durable, and can be used in extremely hot or cold climates.