Fabric tensile structures are designed to blend form, function, and sustainability. Crafted with precision and meticulously engineered, tensile fabric structures redefine shade solutions in the modern era. They provide an optimal balance of shelter, visual appeal, and cost-efficiency.

As owners and leaders in your industries, choosing the right shade solution is essential. We aim to empower you with the knowledge and insights needed to make informed decisions. Learn more about the main components of tensile fabric structures and the top applications of tension shade structures below.

What Is a Tensile Shade Structure?

A tensile fabric shade structure is a system crafted from a flexible membrane held tight by steel cables or wire. How do these structures stay up? It’s due to their ability to work under tensile stress, making them a versatile and durable architectural choice. Tensile fabric structures utilize thin yet resilient canvases stretched across cables to create surfaces capable of withstanding various forces.

Why are various industries investing in tensile shade structures? Here are their main advantages:

- Versatility: These structures come in various shapes and sizes, making them suitable for different applications, from shading walkways to covering large stadium arenas.

- Lightweight: The lightweight nature of tensile materials reduces the structural load on the surrounding environment, which can be particularly advantageous in certain applications.

- Durability: Although they’re lightweight, these structures are also quite durable. High-quality materials and engineering ensure tensile structures are capable of withstanding various weather conditions, including wind, rain, and snow.

- Quick installation: Compared to more traditional construction methods, tensile structures require minimal installation time.

- Low maintenance: These structures are relatively low maintenance, requiring periodic cleaning and inspection to maintain their appearance and functionality.

- Cost-effective: Tensile structures are often more cost-effective than traditional building methods due to reduced material usage and faster construction.

Components of Tensile Fabric Structures

Understanding the key components that form the foundation of these architectural structures is essential for business owners and decision-makers. Each component plays a crucial role in shaping a durable, versatile shade solution that stands the test of time.

- Membranes: Membranes are made from high-performance fabrics, such as PVC-coated polyester or PTFE-coated glass fibers. Their primary role is to provide shade, protection, and visual appeal. Membranes come in various shapes, allowing for creative and customized designs.

- Cables: Steel cables create the tension necessary to support the membranes. Load-bearing cables handle external forces and are fixed at the highest points. Stabilizing cables reinforce load-bearing cables and ensure structural integrity. By crossing orthogonally, they prevent deformations.

- Supporting structures: These are typically masts or poles that provide the necessary framework to anchor the cables and membranes. The choice of supporting structures depends on the specific design and function of the tensile fabric structure.

The interaction of these components is the essence of a fabric tensile structure. Membranes provide shade and shelter, cables distribute forces, and supporting structures give form and stability. Together, they create an architectural masterpiece that blends aesthetics with functionality.

Top Applications for Tensile Structures

Within the architectural industry, tensile fabric structures find their niche in three distinct applications, namely in transportation, athletics, and corporate settings. Business leaders and decision-makers can utilize the adaptability and proficiency of these structures to redefine architectural solutions, fulfilling their unique requirements.

Transportation Facilities

Transportation facilities stand as one of the top applications for tensile fabric structures due to a combination of practicality, aesthetics, and cost-effectiveness.

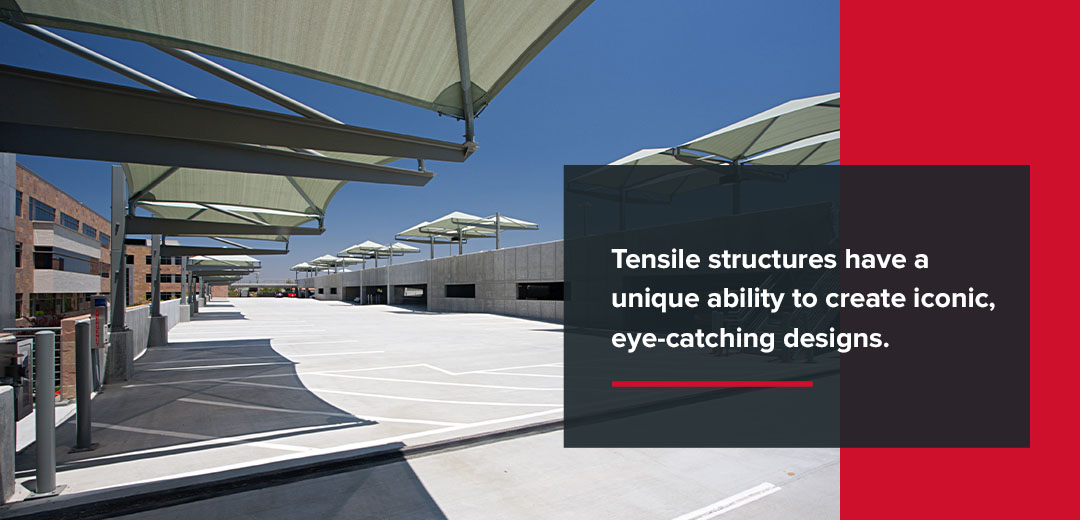

- Visual appeal: Tensile structures have a unique ability to create iconic, eye-catching designs. At transportation hubs, such as airport terminals, they make a powerful first impression, offering passengers a welcoming and memorable experience.

- Cost-effective solutions: Tensile fabric structures are relatively lightweight and require fewer supporting elements compared to traditional architectural solutions. This means cost savings, making them an attractive choice for transportation projects.

- Passenger comfort: In transportation hubs like airport terminals, tensile canopies provide passengers with comfortable, sheltered waiting areas. Whether protecting against the harsh sun or unexpected rain, these structures provide travelers with a pleasant experience.

- Customized designs: Tensile structures can be tailored to fit the unique requirements of each transportation facility. This adaptability ensures these structures are more than just functional and include innovative and forward-thinking design.